FAS-LT MIXERS FOR PROPANE-AIR TECHNOLOGY

SNG MIXER UNITS /Propan-Air-Mixing units

FAS-LT MIXERS in VERSION "COMFORT"

SNG mixing units (propane-air mixing units) are generally intended to replace natural gas units and are used as such. The use of PROPANE-AIR mixing unit allows the consumer to dispense with natural gas completely.

The new generation of FAS mixing units meets the most demanding requirements of the industry:

- control of Wobbe-index

- SIL2 monitoring and shutdown

- Reliable mixing process

- Outputs from 3 mW/h up to 60 mW/h

- Output pressures from 50 mbar up to 3 bar

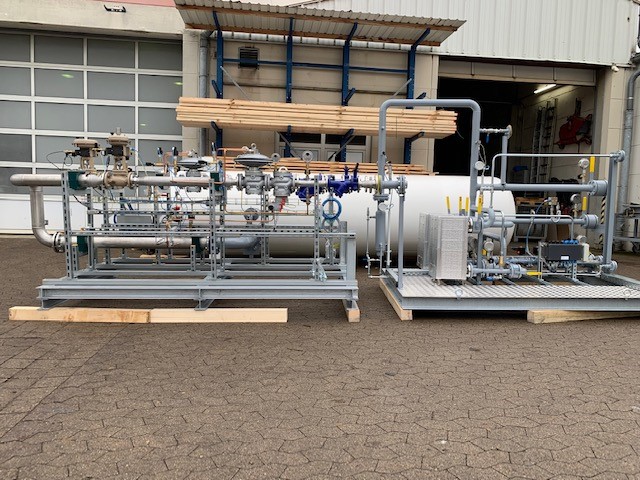

FAS-SNG MIXING PLANTS (PROPANE-AIR PLANTS) are usually built on a steel frame.

According to customer requirements, FAS-SNG mixing units (PROPANE-AIR units) are combined with liquid gas vaporisers.

The evaporator capacities are adapted to the capacities of the mixing plant (from 50 kg/h up to 25 000 kg/h).

As a leading manufacturer of liquid gas vaporizers, FAS is able to equip a mixing unit with different vaporizer types, e.g. FAS 2000 (electrical dry-type vaporizer) or FAS 3000 (hot water vaporizer).

FAS-SNG mixing unit (PROPANE-AIR SYSTEM) can be largely varied.

The safety chain in modern FAS-SNG mixing plants is particularly noteworthy:

- in the event of a malfunction of a gas mixing system, the system sends an alarm.

- comparison of the oxygen content, calculated from the flow measurements, to the analysis value and, if necessary, alarming or switching in case of critical deviation.

- SIL 2 Monitoring of the oxygen content in the gas mixture and shutdown of the air admixture in the event of a limit value violation. Safety-related shutdown of the gas-mixing line.

- In the event of failure of the regular power supply the control valves close. The same happens if the control system fails.

- This shutdown chain is carried out in the same way in the event of limit value violations that no longer allow the desired gas mixture to be produced, as well as in the event of equipment failure.

- The same happens if a measuring instrument in the gas mixing line fails.

- The sample gas flow is monitored via the min. limit value of a flow switch for analysis. Sample gas failure also initiates an alarm.

- If the gas analyser fails, the control valves close.

- If the pressure regulators fail, the SAVs close.

- Gas non-return valves are installed in the gas lines.

|

SNG-MIXING UNIT (PROPANE-AIR) |

Performance mW |

Pressure |

Note |

|

FAS-LT 5 |

up to 5 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 10 |

up to 10 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 15 |

up to 15 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 20 |

up to 20 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 25 |

up to 25 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 30 |

up to 30 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 40 |

up to 40 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 50 |

up to 50 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

|

FAS-LT 60 |

up to 60 |

up to 3 bar |

Available as a mixing unit only or in combination with FAS2000/FAS3000 |

The following information is required for the correct design of the mixing plant:

|

1 |

natural gas consumption to be replaced at peak Nm³/h |

required item 1 or 2 or 3 |

|

|

2 |

natural gas consumption to be replaced at peak kg/h |

required item 1 or 2 or 3 |

|

|

3 |

natural gas consumption to be replaced at peak mW/h |

required item 1 or 2 or 3 |

|

|

4 |

desired pressure after the mixing unit, bar |

||

|

5 |

Medium: propane, butane, LPG-mixture ___propane/___butane |

||

|

6 |

Need for WOBBE INDEX regulation |

YES / NO |

|

|

7 |

Calorific value (Wobbe-range) |

Hg = ......... kJ/cm3 / ....... kWh/Sm3 |

if known / if possible |

**************************************************************************************************************************************************************************************

FAS-LT MIXERS in VERSION "COMBI MANUAL"

The combined mixing system is built in a steel cabinet and forms a closed combination of LPG vaporizer system and a PROPANE-AIR (SNG) MIXING SYSTEM.

Operating data:

• Maximum capacity: 1; 2; 4 or 6 MW

• Output pressure: 1.5 barg (adjustable)

• 20...40% air in standard propane (Wobbe below: 11.4...12.3 kWh/m³)

• Inlet pressure propane: 6.5 barg

• Compressed air from on-site supply: 4.5 barg

• Liquefied gas inlet: flange DN 25, DN 40 or DN 50

• Air inlet: flange DN 25

• Mixed gas outlet: flange DN 25 or DN 50

The automated control section of the mixing system is set up in a separate field cabinet. It must be installed outside the Ex zone.

Operation advantages are:

• Manual adjustment via metering valves, with data reading via pressure gauge and two flow meters

• Filter in every gas line

• Check valves in each gas line

• Pneumatic dome pressure regulators to regulate gas inlet pressures

• Differential pressure monitoring between propane and air

• Variable area flow meters for propane and air adapted to flow• Automated shut-off valve in the air line

• Manual metering valves in each gas line, adapted to the flow rate

• Automated shut-off valve in the mixed gas line

• Possibility to relieve the pressure on the pipe system

• O2 limit concentration monitoring with O2 sensor for EXII 2G EX db IIC T4 GB classification (internal and external explosion protection) • Calibration without external gas connections, possibility of flushing with inert gas

• All cables on terminal box

• Control and evaluation of gas analysis in a separate field housing with 4” touch screen, outside the Ex zone

| UNIT |

Caqpacity MW |

LPG Supply, kg/h |

V AIR, Nm3/h |

V SNG MIX Nm3/h |

| FAS-LT-1-1,5 | 0,2-1 | 20-98 | 3,5-23 | 66-72 |

| FAS-LT-2-1,5 | 1-2 | 98-193 | 17-45 | 131-142 |

| FAS-LT-4-1,5 | 3-4 | 289-386 | 52-90 | 263-284 |

| FAS-LT-6-1,5 | 5-6 | 482-577 | 86-134 | 393-425 |

FAS LPG-air-mixing units in ventury design are available by request in following executions:

- Propane-air mixing unit FAS-4000 LP (Low Pressure execution) in cabinet construction

- Propane-air mixing unit FAS-4000 HP (High Pressure execution) in cabinet construction

- Propane-air mixing unit FAS-4000 as “cascade execution” in cabinet construction

- Propane-air mixing unit FAS-4000 in combination with dry-type vaporizer FAS-2000, completely mounted in container

- Propane-air mixing unit FAS-4000 in combination with hot water vaporizer FAS-3000, completely mounted in container

- Special executions according to customer specification on request.

For more information please download flyer