FITTINGS & ACCESSORIES FOR LNG & CRYOGENICS

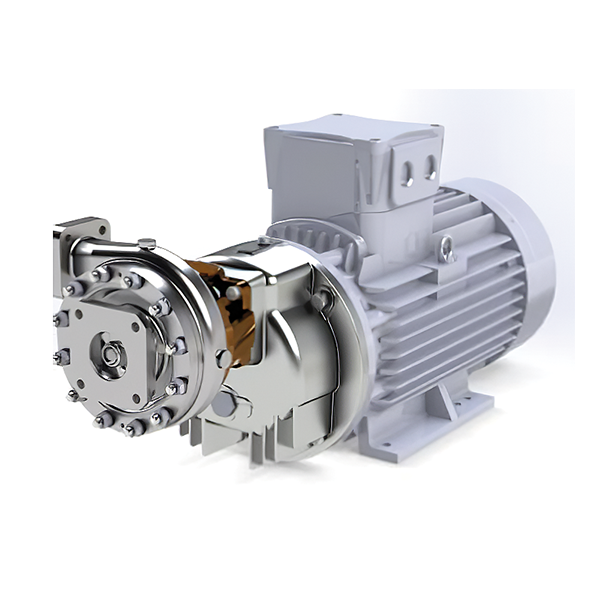

APPLICATIONS FOR CRYOGENIC CENTRIFUGAL PUMPS:

- Unloading of road tankers, loading and unloading of storage and ISO containers

- Securing processes, applications for petrochemical industry

- Special applications with differential pressure and flow rates on customer request

Cryogenic centrifugal pump unit SGM 185 for LNG

- Max. capacity – 550 l/min. (with max. differential pressure 6 bar)

- Electric motor – 11 kW (50 Hz 400 V, ATEX Ex-D IIB T4)

- With terminal box and drive

- Rulon mechanical sealing

- Inductor for minimization of required NPSH

Cryogenic centrifugal pump unit DSM 230 for LNG

- Max. capacity – 1000 l/min. (with max. differential pressure 3 bar)

- Motor – 11 kW (50 Hz 400 V, ATEX Ex-D IIB T4)

- With connection box and direct clutch gearbox

- Rulon mechanical sealing

- Inductor for minimization of required NPSH

For more information please click here FAS catalogue

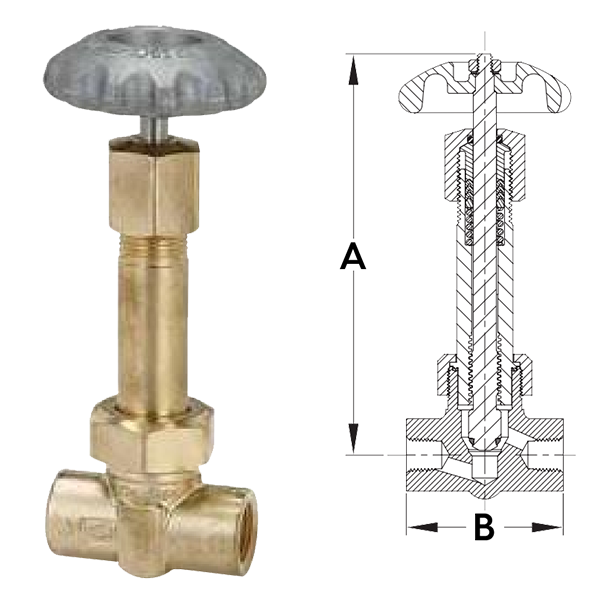

- REGO Safety relief valves – series PRV, AR, UA etc.

- REGO Globe valves - Series BB, BK, BKA, 222, 202x, SKB, SK, 210, 231, 232, 2500, 2550

- REGO Gate valves - Series 322, 326, 302, 306, 310, 310X, 110, 110WX, LOX

- REGO Check valves - Series 8500, 840, 846M, 886, CG

- REGO Internal valves - Series TA 3217 C & TA 3217 DA

- REGO Regulators - Series 1780, BR 1780, 1682 M, C-1682 M, M 2523 HP, 4403, 4686,4289, 4291, LV 4286-10, LV 4289-10

- REGO High pressure valves - Series HP 9560, 7160

- REGO CRYO and LNG safety valves

- REGO CRYO and LNG check valves

- REGO CRYO and LNG gate valves

- REGO CRYO and LNG globe valves

- REGO CRYO and LNG regulators

- REGO CRYO- and LNG short stem valves

FAS is RegO Master Distributor. We offer the complete range of RegO products. For more information please have a look in the REGO catalogue

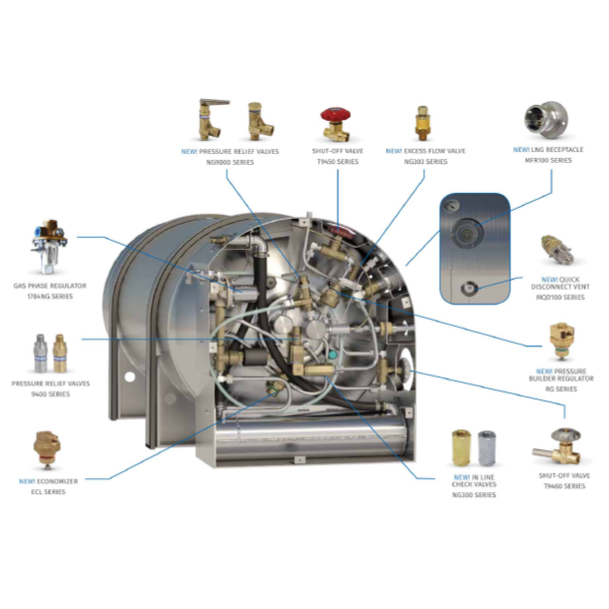

REGO PRODUCTS CRYOGENIC APPLICATIONS

- REGO Cryogenic Valves

- Series T9450 & T9460

- Series ES8450

- Series BK9450 & BK9470

- REGO-LOK 9464

- Series 9464

- Pressure regulators & economizer

- Series RG, CB 504, ECL, CBH, PB, CBC & LCR

FITTINGS FOR CRYOGENICS

- Straightway valves

- Angle valves

- Gate valves

- Filling modules

- Actuated valves and drives

- Pressure regulators

- Back pressure check valves

- Strainers

- Safety relief valves

- Overflow valves

- Retractable assemblies

We offer the complete range of HEROSE fittings for cryogenics. For more detailed information about these fittings, please download the HEROSE catalogue.

LNGmass CORIOLIS FLOW METER TECHNOLOGY

- Proven measuring technology: a convincing alternative to conventional volumetric measuring methods

- Direct mass measurement: including conversion in different unit of quantity

- Space-saving compact design: smallest flow meter for LNG dispenser worldwide

- No inlet and outlet pipe sections required

- Cost-effective operation: maintenance-free, no movable parts

- Robust: precise measurement also with temperatures of -196°C (-321°F)

- Optimal supervision of refueling process: simultaneous measuring of mass flow and temperature

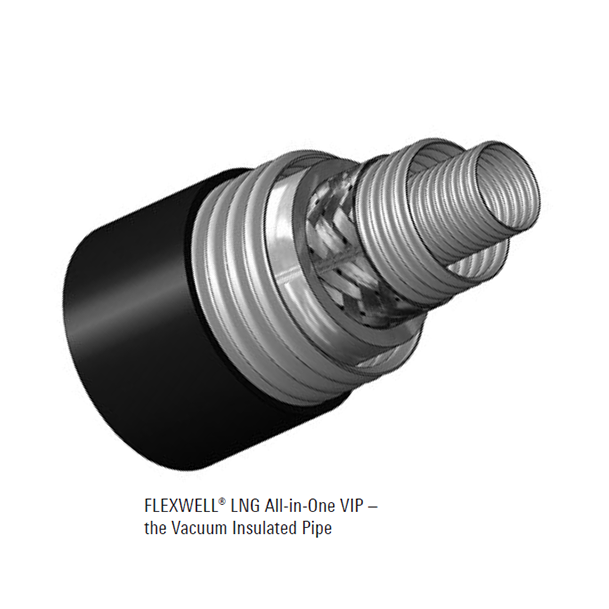

FLEXWELL LNG All-in-One is a unique and cost-effective LNG pipe system which can be installed in LNG filling stations as endless LNG, circulation and gas return line: all at the same time – ALL-IN-ONE!

Composition of FLEXWELL LNG All-in One

Due to the continuous manufacturing process of the flexible stainless steel hoses the All-in-one can be produced endless und thus presents a flexible pipe system quickly to install. It does not have to be welded or screwed on site.

The multilayer structure of the FLEXWELL LNG All-in-One enables a combination of:

- LNG flow line

- LNG return line

- BOG return

- Vacuum superinsulation

Learn more – Download Brugg LNG All-in-one